1. Precautions for product use

●The packaged products should be placed in a dry environment, and the humidity should be controlled below 60% RH. If it exceeds 60% RH, it needs to be dehumidified, especially in spring or mildew weather. The ambient temperature should be controlled below 30℃, and if it exceeds 30℃, it needs to be cooled down;

●The product will be stored for more than one month and it will take 6 hours of aging before use before it can be used normally. The aging method is: full brightness setting is 10% 1H, full brightness setting is 30% 1H, full brightness setting is 60% 2H, full brightness setting is 80% 1H, full brightness setting is 100% 1H (the brightness gradually increases and aging);

●Do not drop, push, squeeze or press the unit plate during use and transportation to avoid damaging the display screen;

●Display screens used in special environments (1. Beachside, swimming pool, bathing ground, basement, tunnel; 2. Chemical environment, sulfurized environment, halogen environment; 3. Sand and dusty environment; 4. Strong ultraviolet environment; 5. Strong electromagnetic field environment; 6. Ambient less than -20 degrees and greater than +40 degrees), please inform us before placing an order;

●People who come into contact with the product must wear electrostatic bracelets and electrostatic gloves, and various tools must be strictly grounded during the assembly process;

●Before unboxing, confirm whether it is a module of the same batch. Products with different batch numbers cannot be installed on one screen, otherwise color blocks (mosaics) will occur on the display;

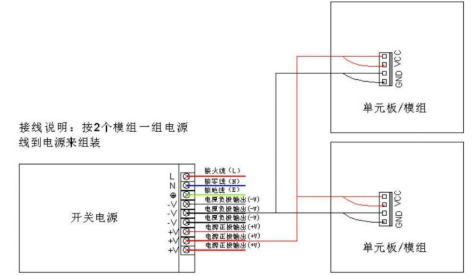

●When installing the module, please be careful to check the correct wiring of the power port. The positive and negative poles must correspond to each other before power is turned on. If the positive and negative poles are connected in reverse, the module will be burned and the power must be cut off in time to avoid fire. Use a special switching power supply for LED display screens. The limit working voltage of the module is less than 5V, and it must not be directly connected to 220V, otherwise the entire screen module will be burned;

●When wiring the power supply, make sure that the terminal connector screws are tightened to prevent loosening and causing large contact resistance to cause burning wire or product damage. M4 screw torque 6-8 Kgf/㎝², M3 screw torque 4-6 Kgf/㎝²;

●It is prohibited to assemble the unit board when power is turned on. The main power input should be disconnected and the unit board should be assembled on the wall. It is not allowed to assemble the power cord and signal cord with insertion;

●In the process of lighting, people are prohibited from touching and touching the LED display screen to avoid electrostatic breakdown of LED lamps, chips and other components caused by human friction;

●The installation angle and height must be appropriate, and sharp corners must be packaged to prevent the hard shell from harming the human body;

●Within the relative humidity range of 10% to 65%RH, it is recommended to turn on the display once a day, and use it normally for more than 4 hours each time to remove moisture on the display; if the humidity is higher than 65%RH or the weather is back, the use environment needs to be dehumidified. It is recommended to use it normally for more than 8 hours a day, and close the relevant doors and windows at night to prevent the display from getting damp and causing adverse effects.

●When the display screen is not used for a long time, it is necessary to reduce the brightness of the entire screen by 50% in advance for 12 hours to play and preheat for "dehumidification" 12H to avoid damage to the light tube after the LED screen is damp

●To ensure the service life of the LED, please do not display only still images or text for a long time, which will cause severe attenuation of the brightness of the lamp or

This causes batch dead light problem, please play scrolling screen or text.

●When disassembly and assemble, no sweat or other liquids drip on the display screen. If there is any drip, alcohol is required to clean the drop position of the product to prevent liquid corrosion and damage to the product.

2. Scope of application

It is mainly used in military exercise command systems, public safety display command systems, studios, radio and television media display systems and other fields.

3. Product description

●Product version: The refresh rate of this product is divided into regular version (3840Hz) and TOP version (3840Hz). See 5.4 for details;

●Indoor D series unified kit size and hole position, the box hole position can be versatile; it can be paired with bevel kit to splice at right angles;

● Choose a high-quality surface sticker 1515 special lamp, the ink color of the screen is uniform, the consistency is good, and the screen color is more realistically restored;

●LED high-density full-color screen dedicated driver chip: eliminates ghost shadows and open-circuit crosses, increase the frequency double refresh rate by 2/4/8 times, improves functions such as low gray color bias, low gray poke dots and dark lines, and has anti-interference ability;

●High-definition display: High resolution brings high-definition and delicate display effects, and can achieve the real-time display of pixels on pixels, without flickering and graininess;

●Extra large viewing angle: horizontal viewing angle can reach above 140°, watch from multiple directions, and the display effect is consistent;

●High grayscale, ultra-wideband load: 12~14Bits adjustable grayscale, clear and realistic display quality, bright and smooth playback effect;

●Good flatness: Independently developed and produced, the multi-reinforced structural bottom shell is not easy to deform;

●Simple installation and convenient maintenance: The bottom shell of the unit plate adopts a quick-removal magnetic suction rear cover, which is easy to install.

Unit board picture

Front view |

| Back view |

|

(Three Generation Kit) |

(Note: The pictures are for reference only, everything shall be subject to the actual product)

4. Product technical parameters

Unit board technical parameters |

Pixel spacing | 2mm | Input voltage (DC) | 4.2-5.0V | Module weight | 0.39 ± 0.01kg |

Pixel composition | 1R1G1B | Unit board power | ≤ 15W | Kit Materials | Polycarbonate PC material |

Length*width*height | 320*160*15mm | *** Current | 2.7 ± 0.3A | Copper nut | 6*8*M4 |

Structural features | Light drive unite | Pixel density | 250000Dots/㎡ | Driver method | 1/40 Sweep constant current drive |

Light tube type | SMD1515 | Unit board resolution | 160*80= 12800Dots |

|

|

Optional control card | Kelesta G612C, Kelest 5A-75E, Nova DH7516, Lingxingyu Rv908M |

Color temperature (K) | 3000-15960 Adjustable | Unit area (㎡) | 0.0512 |

|

|

Box technical parameters |

Recommended box size | 640mm*480mm*70mm (Length*width*height) | Box material | Die-cast aluminum/magnesium alloy |

Box resolution | 320*240=76800 Dots | ***Power consumption | ≤ 90W |

Box area | 0.3072 ㎡ | Average power consumption | ≤ 36W |

Box weight | 4.1 ± 0.05kg |

|

|

Screen body technical parameters |

Brightness range | 400 - 450cd/㎡ | Note: Over-promoting lofty brightness will seriously sacrifice the life of the display |

Horizontal viewing angle of screen | 140 ± 10 ° | Vertical viewing angle of screen | 140 ± 10 ° |

***Sight range | 2.5m | Usage environment | indoor |

Power per square module | ≤ 390.6w/m² | Brightness uniformity | ≥ 97% |

Distribution power (power per square meter ÷ 78% ÷ 85%) | 589.2w/m² |

System control parameters |

Grayscale | Red, green, blue 12-14bits | Show color | 4398 billion |

Frame change frequency | ≥ 60 frames/second | Refresh frequency | ≥ 3840Hz (full grayscale field) |

Control method | Computer control, point by point, video synchronization, real-time display | Brightness adjustment | Level 256 manual/automatic |

Input signal | DVI/VGA, video (multiple formats), RGBHV, composite video signal, S-VIDEO, Ypbpr(HDTV) |

System working characteristics |

Theoretical service life | ≥100,000 hours | Average failure-free time | ≥10,000 hours |

Decay rate (3 years of work) | ≤15% | Continuous out-of-control points | 0 |

Operating temperature range | -10 to 40℃ | Blind Spot Rate | <0.0001 |

Screen horizontal flatness | <1mm/㎡ | Working humidity range | 10% to 65% RH (no condensation) |

Vertical flatness of the screen | <1mm/㎡ |

|

|

5.2 LED die parameters (1515 lamp beads)

Glowing color | Wavelength (nm) | Luminous intensity (mcd | Reverse current IR | Test conditions | Luminous angle (Typ.) | Forward voltage (v)(Typ.) |

(Typ.) | MIN | MAX | When VR = 10V |

R | 617-621 | 36 | 45 | 0.2 | IF=8ma | 115° | 1.8-2.4 |

G | 515-518 | 108 | 135 | 0.2 | IF=5ma | 115° | 2.4-3.2 |

B | 463-466 | twenty three | 29 | 0.2 | IF=3ma | 115° | 2.5-3.3 |

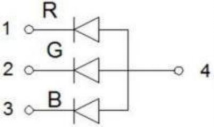

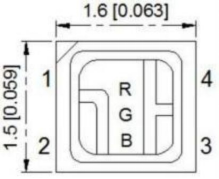

1515 Lamp Bead Product Rules

1515 Polarity of lamp beads

5.3 Pin line signal pin definition (HUB75)

Foot map | Pin function description |

PIN pin map | Foot number | Function | Remark | Foot number | Function | Remark |

1 | ● | ● | 2 | 1 | R1 | Red data signal | 2 | G1 | Green data signal |

3 | ● | ● | 4 | 3 | B1 | Blue data signal | 4 | GND | Power ground |

5 | ● | ● | 6 | 5 | R2 | Red data signal | 6 | G2 | Green data signal |

7 | ● | ● | 8 | 7 | B2 | Blue data signal | 8 | GND | Power ground |

9 | ● | ● | 10 | 9 | A | A Scan the signal | 10 | B | B Scan the signal |

11 | ● | ● | 12 | 11 | C | C Scan the signal | 12 | GND | Power ground |

13 | ● | ● | 14 | 13 | CLK | Clock latch signal | 14 | LAT | Shift latch signal |

15 | ● | ● | 16 | 15 | OE | Enable signal | 16 | GND | Power ground |

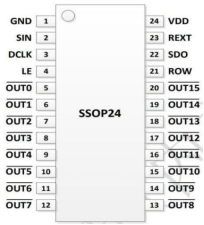

5.4 Driver IC

Constant current driver IC: 4K refresh rate

This chip is a driver IC specially designed for full-color LED display screens, with 16-channel PWM constant current outputs, and supports 1~64 scans to scan any scan. The current precision control technology is used on-chip, so that the current error between chips is less than ±2.0% and the channel error is less than ±2.0%. Different external resistors can be used to adjust the output stage current magnitude to accurately control the LED's luminous brightness.

Regular version | TOP version |

High gray independent display, high refresh rate | Low gray and high brush, higher contrast |

Eliminate open-way caterpillars and bad point crosses | Eliminate open-way caterpillars and bad point crosses |

Integrated lamp bead protection circuit to reduce lamp bead damage | Effectively solve high contrast coupling and cross-plate color difference |

Improve low gray blocks and dark lines | Effectively solve low gray blocks, color casts, pockmarks, and dark lines |

| Dynamic energy saving, eliminating useless power consumption |

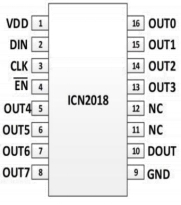

Line Driver IC

This line driver chip is a line driver tube designed specifically for LED scanning screens. It integrates a serial decoding circuit and power PMOS tube. It adopts the SOP16 package type and integrates functions such as anti-burn power tube, anti-ghosting, and LED lamp bead protection.

Features

Integrated serial decoding circuit

Integrated 8 power PMOS output PIN

Supports *** continuous current of 2.5A

8 adjustable potential

5.5 Pin Definition

Constant current driver IC

Line Driver IC

Pin Description

name | Constant current driver IC function introduction |

GND | Chip ground |

SIN | Shift register serial data input port |

SCLK | Shift register clock input port |

LE | According to the latch end of the instruction, different LE lengths represent different instructions |

OUT0~OUT15 | Constant current source output port |

GLK | Display clock |

SDO | Shift register serial data output port |

R-EXT | Constant current setting port, external resistor to ground set the constant current source current value |

VDD | Power supply terminal |

name | Introduction to the function of the row driver IC |

VDD | Power supply terminal |

DIN | Shift register serial data input port |

EN | Enable the control terminal |

CLK | Shift register input clock |

OUT0~OUT7 | 8 power output ports |

GND | Grounding end |

DOUT | Shift register serial data output port |

NC | Hanging in the air |

6. Power and control card recommended with load

It is recommended to use a power supply | Unit board brightness | Recommended load count |

Recommended one | 4.5V 40A |

400-450cd/㎡ | 6~8 |

Recommended 2 | 4.2V 40A | 400-450cd/㎡ | 6~8 |

|

|

Note: It needs to be loaded according to the standard loader

Kaishida |

G612C Recommended with load | G616C Recommended with load |

1 width 8 height | 160*640 points | 1 width 10 height | 160*800 points |

Carlett |

5A75E Recommended with load |

|

|

1 width 12 height | 160*960 points |

|

|

Nova |

DH7512 Recommended with load | DH7516 Recommended with load |

1 width 12 height | 160*960 points | 1 width 10 height | 160*800 points |

7. Installation hole position map

Note: If you are making a box, please inform and confirm the hole position map of the order product in advance. For details, please refer to the CAD diagram; the unit of all sizes is mm.

8. Box diagram

Recommended use 640*480mm box hole position map

Note: The unit plate and box adopt magnetic suction and pre-maintenance technology to facilitate disassembly and assemble; all sizes are mm.

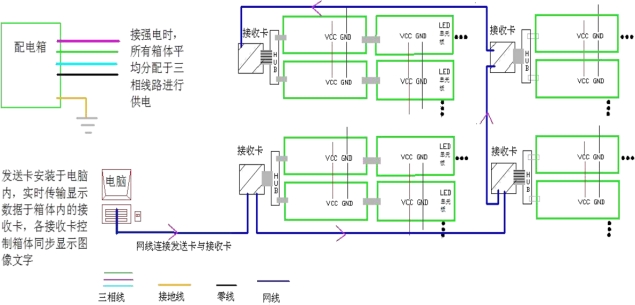

9. Simple diagram of electrical connection of the display screen

10. Entire screen acceptance requirements and methods

●Screen brightness: Turn the screen to fully lit, adjust the brightness efficiency of the test software to 80% on the computer, and use a light gun to measure the brightness of the screen within 10 minutes. When measuring brightness, the light gun is required to be aimed at the screen. *** is to measure the time the light gun can keep level with the screen, ensure that the black position of the observation window covers more than 16 pixels, and adjust the focal length so that you can clearly see the luminous point before measuring and reading;

●Visible angle: When measuring, the person stands at 140° on the left and right of the screen, and watches at 70° on the bottom of the screen (i.e., the vertical viewing angle of the screen is 140°). The screen requires no obvious dark spots or obvious dark blocks;

●Grounding: The switch power supply shell, box and screen structure are correctly grounded, the grounding point is correctly marked, and the grounding resistance is required to be ≤ 10 ohms, and inspection is carried out every six months;

●Lightning protection treatment: The building requires lightning rods or lightning belt facilities and is effectively grounded. The distribution box is required to have a distribution box and a surge protector. The lightning protection facilities are inspected every six months.